Next spray the area with a coat of eastwood rust encapsulator which penetrates deeply into the pits and adheres to the metal keeping the rust from coming back or spreading by absorbing moisture.

Plasma spray rusty sheet metal.

If necessary apply a new coat of paint to the area.

In this video im showing you the process i use to do small rust repairs where a complete panel.

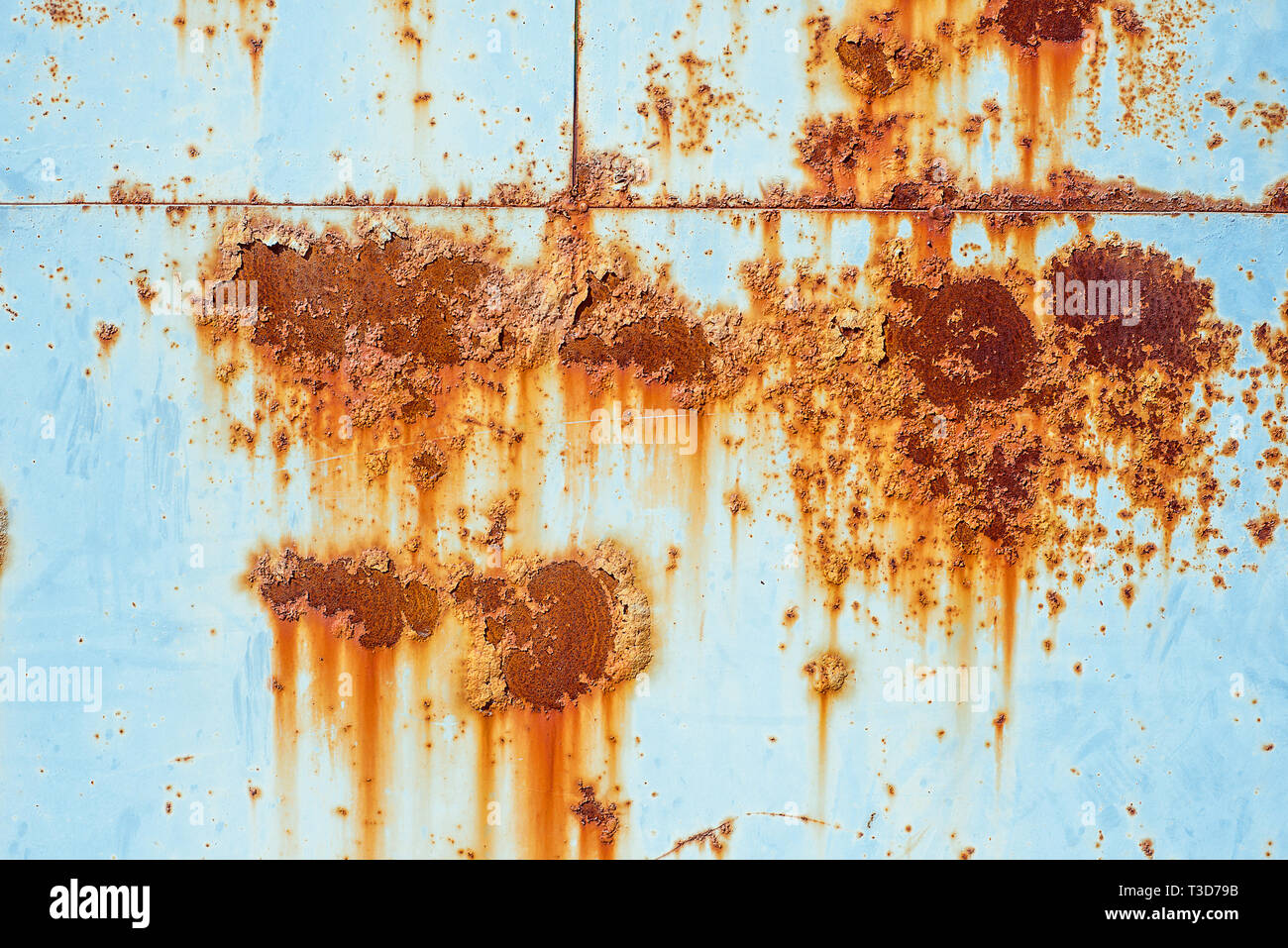

We are a small custom metal shop that has a rust finish on some of our items.

07 21 2007 03 25 pm 10.

The problem is that we are having a difficult time sealing the rust finish typically on the towel bars and towel rings where they are exposed to moisture.

No two pieces will ever be the same.

Here s a quick tip to help you slice through this material with ease.

Industrial metal supply is the southland s largest supplier of all types of metal and metalworking accessories including rust prevention products.

A weed torch connected to a propane tank makes quick work of the job but is not necessary.

Pour some white vinegar into the spray bottle and then spray every inch of the metal object.

Next spray the chemicals onto the metal and see how the colors change.

Then scrub with warm water and soap and apply a metal conditioner or other protective coating to prevent further oxidation.

This can help matters some but it doesn t remove all the loose scale and air gas as pickling does.

The 300 amps with 1 2mm wire is good at removing mill scale.

No imperfections no pits and valleys no loose scale nothing to hinder a constant focus point and consistent depth of focus.

So you ve prepped the metal.

Does your project require you to cut through sheet metal.

See more ideas about plasma cutter plasma cutter art plasma.

A discussion started in 2001 but continuing through 2020.

Heat the metal up the fish and the large 4 x 1 sheet of metal with a weed or blow torch.

Now your steel will be ready for the main event.

Here s a few tips on repairing rust holes in car body panels.

May 24 2012 explore laurie potter s board plasma cutter projects followed by 161 people on pinterest.

Flux core is the best but high co2 gas such as 80 20 ar co2 works ok with plain wire if you can get it into spray arc mode.

Sand the panel and remove all the rust encapsulator except the stuff that soaked into the pits leaving you with mostly bare metal.

Some metal suppliers use buffers to dress the surface and then oil it.